WELDING Preparation

Welding over Picklex® 20 coating, compared to AWS or ASME Code Welding

Picklex® 20 provides much better welding than AWS/ASME code welding.

Welding without removing Mill scale. Eliminates Hydrogen embrittlement (chances of Weld failure is almost Zero). Zero Weld failure since 1998. Acts as an Anti- Spatter.

Welding can be performed over Picklex® 20 coated metal surface after complete drying.

Performance/Benefits of welding through Picklex® 20 coating on Cold rolled steel/Stainless steel:

- Picklex® 20 completely prepares the metal surface by removing mill oil/cutting fluid, flash rust and put a nano weldable conversion coating in One Step.

- Increases weld strength considerably on Cold rolled and Stainless steel.

- Does not cause hydrogen embrittlement and so the chance of weld failure is Zero, which means No Re-work, saving a lot of labor, time & cost. There has been zero welding failure since 1998

- Acts as an Anti-spatter saving labor, time & cost

- After Welding and removal of the weld scale, spraying Picklex® 20 on the welding area provides a very long-term indoor rust protection

- Provides good adhesion of the welding area with the top coating

Performance/Benefits of welding through Picklex® 20 coating on Hot rolled steel with Mill Scale:

- Picklex® 20 completely converts the mill scale to a conversion coating through which welding can be performed after complete drying (dried by Heat Gun). This eliminates removal of the mill scale before Welding.

- Weld strength is still higher compared to the AWS or ASME code welding method (which is performed after removing mill scale).

- Does not cause hydrogen embrittlement. The chances of weld failure is zero

- Acts as an Anti-spatter

- After welding and removal of the weld scale, spraying Picklex® 20 on the welding area provides a very long-term indoor rust protection before top coating

- Provides good adhesion with the top coating

- Saves a lot of labor, time & cost from removal of mill scale and weld spatters

Complete Surface preparation/Pre-treatment of Flash rusted steel

Comparison of the Traditional process and Picklex® 20 Process for Welding

Traditional Process:

Picklex® 20 Process: No Blasting/Sanding/Grinding needed

Present Process:

Sanding/Grinding to remove Rust/Mill scale

Clean the surface

Weld

Picklex® 20 Process:

Picklex® 20 spray/Brush

Wipe off the excess product

Heat Dry with Heat Gun or welding torch

Weld

Welding Prepration

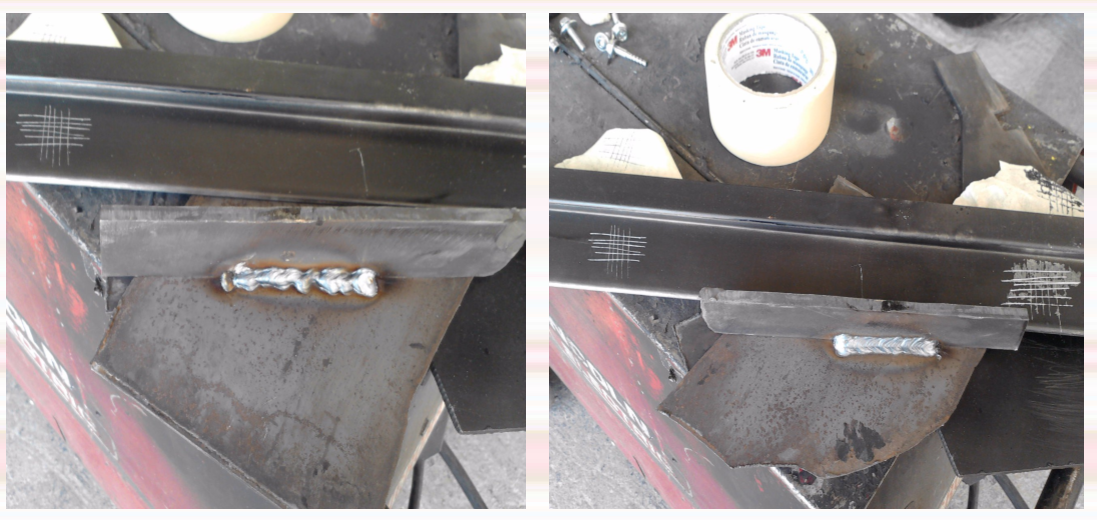

LEFT – WELDING WITHOUT PICKLEX® 20 COATING WELD SPATTER

RIGHT – WELDING OVER PICKLEX® 20 COATING NO WELD SPATTER

Welding Prepration

LEFT – WELDING WITHOUT PICKLEX® 20 COATING WELD SPATTER

RIGHT – WELDING OVER PICKLEX® 20 COATING NO WELD SPATTER

Welding Prepration

LEFT – WELDING WITHOUT PICKLEX® 20 COATING WELD SPATTER

RIGHT – WELDING OVER PICKLEX® 20 COATING NO WELD SPATTER

Welding Prepration

LEFT – WELDING WITHOUT PICKLEX® 20 COATING WELD SPATTER

RIGHT – WELDING OVER PICKLEX® 20 COATING NO WELD SPATTER

Welding Prepration

LEFT-WELDING OVER PICKLEX® 20 COATING NO WELD SPATTER

RIGHT- WELDING WITHOUT PICKLEX® 20 COATING WELD SPATTER